Precision in manufacturing is critical to product quality and long-term reliability. Manual assembly processes often introduce variability through human error, fatigue, and inconsistent techniques. Assembly automation helps eliminate those risks by delivering repeatable, high-precision results at scale.

With the right automated assembly strategy, manufacturers can improve throughput, reduce defects, and maintain consistent quality—without sacrificing flexibility. From robotic workcells to fully integrated assembly lines, today’s automation solutions are designed to support complex manufacturing environments and evolving production demands, reflecting the same shift toward intelligent, data-driven operations highlighted in recent Technavio data on rapidly scaling digital service platforms.

Whether you’re launching a new line or upgrading an existing process, understanding how automated assembly works—and how to choose the right level of automation—can help you maximize your return on investment.

Why Automating Assembly is Important

Precision in High-Volume Manufacturing

In large-scale manufacturing, even minor inconsistencies can lead to major component failure and warranty costs. Precision is vital, and manual assembly’s inherent risk of misalignment causes faults that reduce efficiency and product lifespan.

The right automation strategy can assemble components consistently and accurately, meeting strict quality standards. Even slight misalignments cause faults and reduce efficiency, so automation maintains product quality and reduces costs.

Challenges of Manual Assembly

Manual assembly often leads to:

- Inconsistent placement and alignment

- Premature wear or failure of components

- Contamination from dirt or oil

- Bottlenecks from specialized tools or operator availability

While fixtures and assembly aids can help, manual methods are less reliable and consistent than automation.

How Automated Assembly Systems Work

Machine Components and Mechanisms

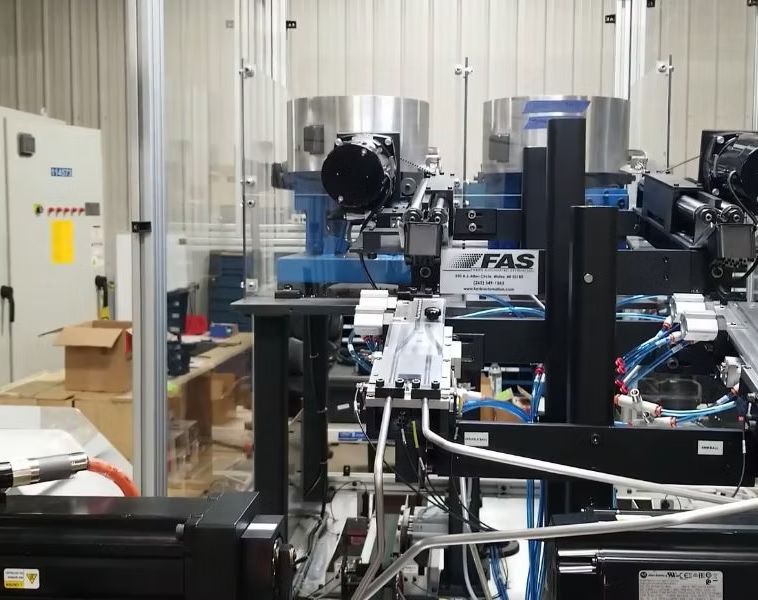

Automated assembly systems leverage advanced robotics for speed, accuracy, and repeatability. These systems precisely position and assemble components, drastically cutting time and errors compared to manual methods.

The system’s main components typically include:

- Gantry robotic systems and programmable logic controllers (PLCs) provide precise control and programmable movement.

- Actuators, sensors and guides ensure perfect alignment and reduce misalignment risk.

- Linear motion parts, like ball screws and guides, guarantee smooth, accurate movement throughout the process.

Automated assembly systems are designed for seamless integration with existing assembly lines, streamlining workflows and reducing manual labor. They synchronize with equipment like conveyor belts, presses, and robotic arms, assembling components at the right point in the production cycle. This integration is crucial for high-volume production and maintaining consistent quality across all units.

This approach ensures the final assembly performs reliably under varying operating conditions, supporting overall manufacturing efficiency and system reliability.

Key Benefits

Faster Production and Higher Efficiency

Automated assembly streamlines production processes and improves efficiency, lowering operational costs. Automation allows for continuous, break-free operation, enabling higher throughput while maintaining consistency. Integrated systems help maintain production flow and reduce downtime.

Improved Accuracy and Consistency

Assembly automation removes much of the variability associated with manual processes, delivering uniform quality across all units. Accuracy and consistency are achieved through automated quality checks, sensor feedback, and in-process monitoring.

Incoming components are verified against specifications, and automated inspection systems perform real-time quality checks throughout the assembly process. Built-in sensors monitor critical parameters, helping maintain precision and repeatability.

This improves manufacturing reliability and overall product dependability.

Choosing the Right Automation Solution

Production Volume and Part Complexity

Fully automated systems are well-suited for high-volume production environments where consistency and speed are critical.

For more complex products or lower-volume runs, semi-automated systems may be more appropriate. Always choose machinery that can scale with both current and future production needs.

You must also consider factors such as the variety of product types your line must handle, specific quality and performance requirements, and the need for advanced inspection or verification equipment.

Fully vs. Semi-Automated Systems

Fully automated systems offer consistent performance and higher output, ideal for mass production, but they typically require a higher upfront investment.

Semi-automated systems combine operator involvement with automation, offering greater flexibility, lower initial costs, and adaptability in environments with frequent variation.

Best Practices

Installation and Downtime Planning

Proper planning is essential for successful automation. Key steps include verifying part tolerances, planning installation to minimize downtime, and thoroughly testing systems before full production deployment.

Thoughtful preparation helps ensure smooth startup and faster time to value.

Operator Training and Maintenance

A well-trained team is essential for early issue detection and long-term system performance. Operators should be trained to monitor system performance, perform routine inspections, and identify early signs of wear or misalignment.

Ongoing training, preventive maintenance, and adherence to safety protocols help extend system life and maintain reliable operation.

Achieve Peak Speed and Accuracy

Investing in assembly automation supports long-term manufacturing success by improving efficiency, consistency, and scalability. Automated systems reduce operational risk while freeing teams to focus on higher-value tasks.

Farris Automation designs custom automation solutions tailored to your product, process, and production goals. Explore how purpose-built automated assembly systems can help you increase output, improve reliability, and stay competitive.

FAQ

Q: What is assembly automation?

A: Assembly automation uses robotic systems and automated processes to assemble components accurately and consistently, reducing human error and improving efficiency.

Q: What are the main benefits of assembly automation?

A: Key benefits include higher production speed, improved quality consistency, reduced operational costs, and increased reliability.

Q: How do automated systems ensure precision?

A: They use sensors, actuators, and in-process inspections to monitor alignment, force, and placement, ensuring consistent quality across all units.

Q: When should I choose fully vs. semi-automated systems?

A: Fully automated systems are best for high-volume, repetitive tasks. Semi-automated systems are better for lower-volume runs or complex, variable products.

Not sure what level of automation is right for your line?

Connect with our team to evaluate your process and identify the best automation strategy.