Our project management strategy is designed to keep you involved and informed during the entire process. You will always have direct access to our design engineers creating your machine to make sure the project is on task, on schedule, and on budget.

Before a contract is signed, we take the time to study your product, define what ‘high risk/low risk’ aspects are found, and layout how each aspect will be managed.

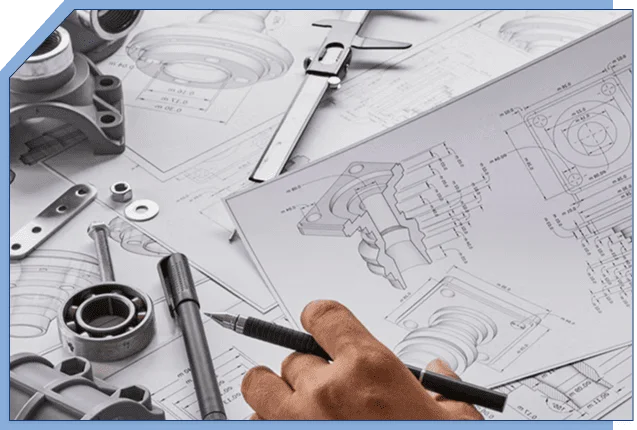

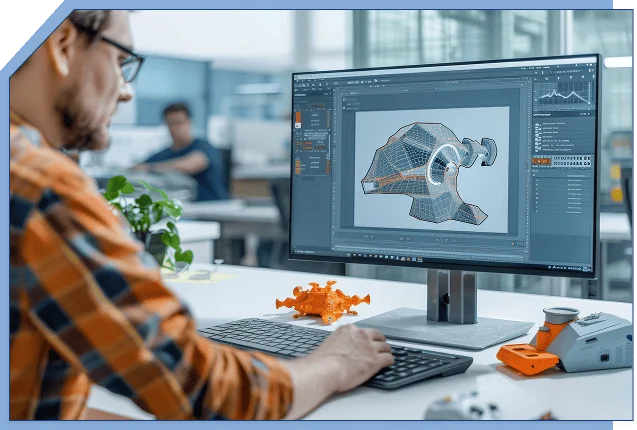

We design using SolidWorks or Creo. Your input during the first few weeks of development is critical to our design team, ensuring the project stays aligned with objectives and on schedule.

Prototypes can be developed to validate high-risk aspects of the design, along with 3D-printed models of the final concept to support progress presentations to upper management.

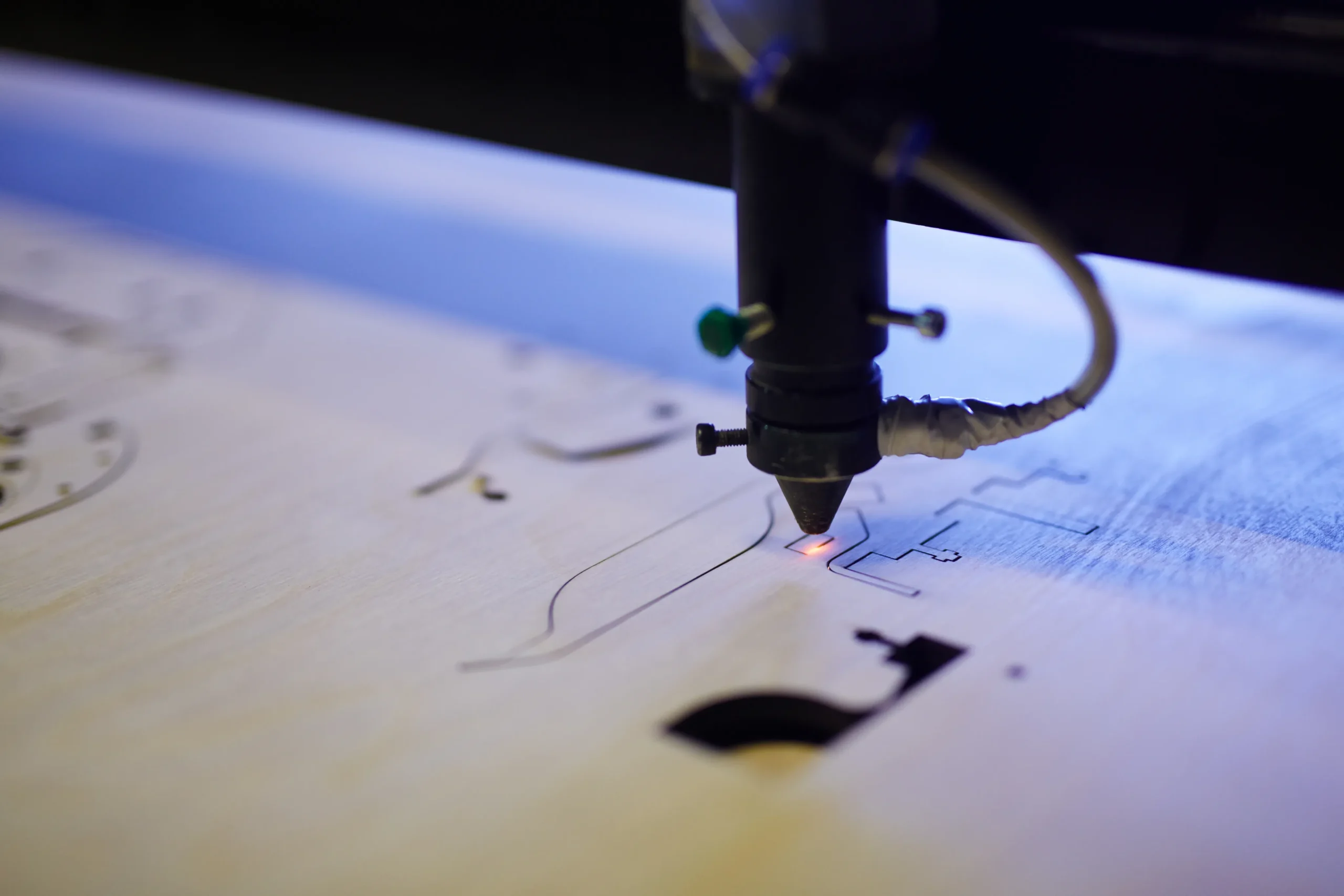

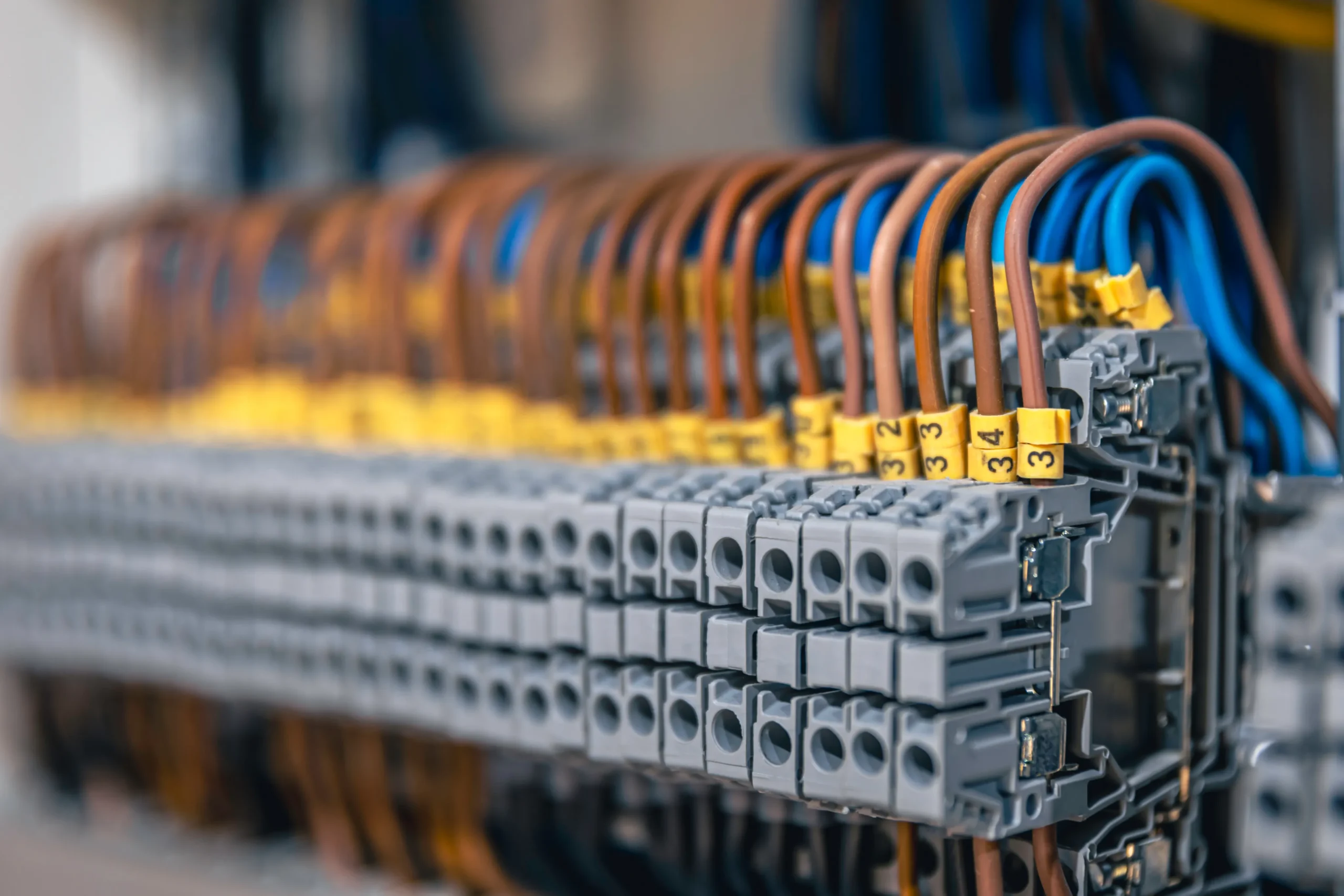

Our in-house machine shop helps keep your projects on schedule while maintaining strict quality standards. We also assemble all electrical panels and operator interfaces internally, giving us greater control over quality, cost, and delivery timelines.

Once programming and testing are complete, our team can handle on-site installation, operator training, and ongoing service support—ensuring a smooth implementation and reliable performance throughout the life of the system.